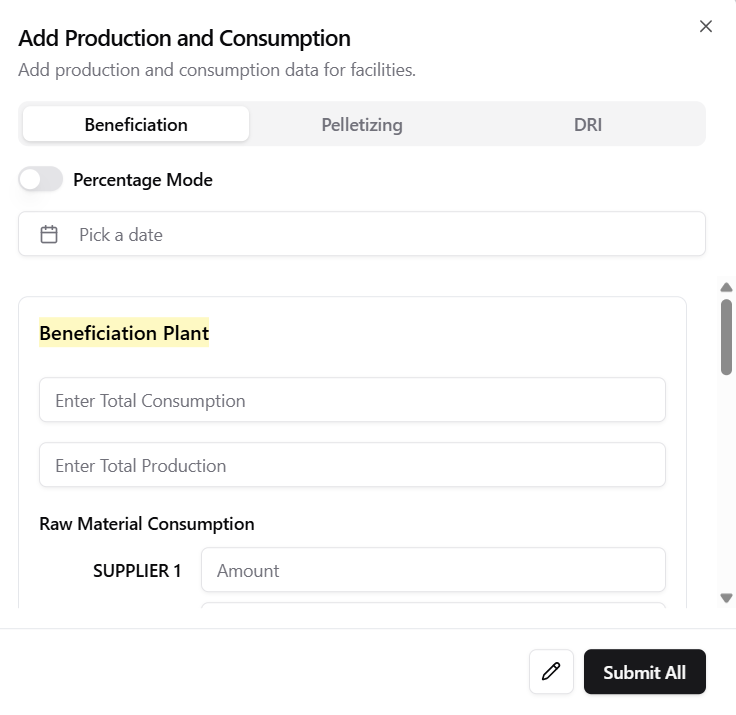

Add Production and Consumption

The Add Production and Consumption feature is a critical component of the Iron Ore Procurement System Software, designed to help users track, record, and manage production outputs and consumption inputs across various processing facilities. This tool provides comprehensive data entry and management capabilities for monitoring operational efficiency and resource utilization.

1. Production Data Entry

The system allows users to add detailed production records for various iron ore processing operations:

Production Types

- DRI Production: Direct Reduced Iron production

- Pellet Production: Iron ore pellet manufacturing output

- Pellet Feed Production: Pellet feed production

Production Data Fields

- Production Date: Date Dof production

- Facility Selection: Choose the specific processing plant or facility

- Product Type: Type of iron ore product being produced

- Quantity: Production volume in metric tonnes

Note:

All values shown in the screenshots and examples are dummy data used to demonstrate functionality. They do not represent actual production or consumption data.

2. Consumption Data Entry

Users can record detailed consumption data for various raw materials and resources:

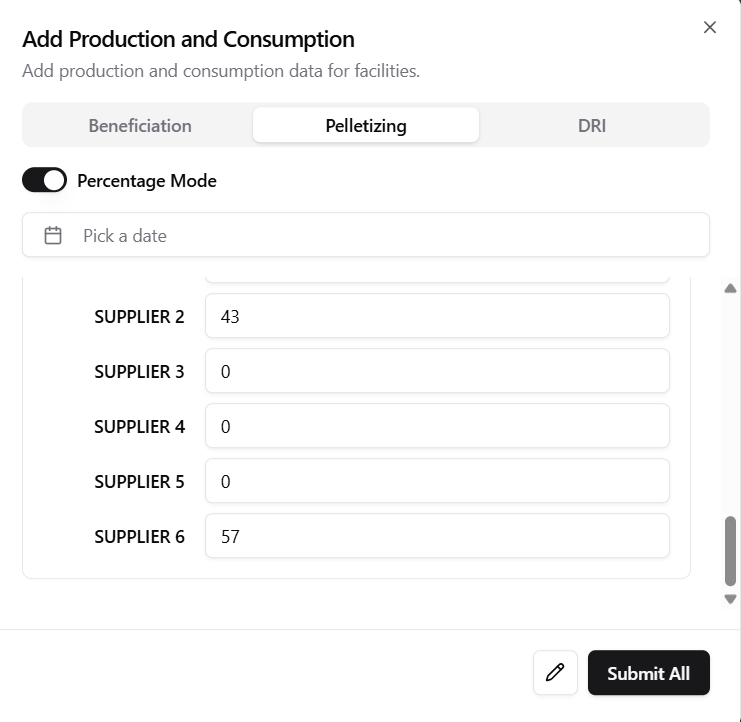

Consumption Categories

- Raw Material Consumption: Raw materials defined in database with unique ID numbers (including but not limited to iron ore, coal, limestone, and any other materials used in the process)

Consumption Data Fields

- Material Type: Specific material or resource being consumed

- Consumption Date: Date of consumption measurement

- Total Quantity Consumed: Total amount used in metric tonnes

- Material Distribution: Percentage allocation for each raw material (system automatically calculates individual quantities)

This detailed consumption tracking helps optimize resource utilization and cost management.

3. Facility Management

The system supports comprehensive facility management capabilities:

Facility Selection

- Multiple Facilities: Support for multiple Beneficiation, Pelletizing and DRI plants

Facility Configuration

- Production Lines: Individual production line management with interconnected input/output tracking between facilities (e.g., Beneficiation plant output can serve as Pelletizing plant input, while Pelletizing plant output can feed into DRI plant production)

This facility-centric approach ensures accurate data attribution and operational oversight.

4. Data Validation and Quality Control

The system includes robust data validation and quality control features:

Input Validation

- Format Validation: Ensure proper data format and units

- Cross-Reference Validation: Check data consistency across related fields

- Duplicate Detection: Identify and prevent duplicate entries

Quality Control

- Data Completeness: Ensure all required fields are completed

- Logical Consistency: Validate logical relationships between data fields

- Historical Comparison: Compare with historical data for anomalies