Generate PDF Report

The Generate Report feature is a comprehensive reporting tool within the Iron Ore Procurement System Software, designed to create detailed PDF reports for operational analysis and decision-making. This tool allows users to generate comprehensive reports covering consumption, production, stock levels, and shipment data across multiple facilities and time periods.

1. Report Generation Overview

The system allows users to create detailed operational reports with flexible parameters:,

Note:

All values shown in the screenshots and examples are dummy data used to demonstrate functionality. They do not represent actual operational data.

Key Features

- Generate daily, monthly, yearly or custom date range reports

- Select multiple facilities for analysis

- View consumption, production, stock and shipment data

- Export professionally formatted PDF reports

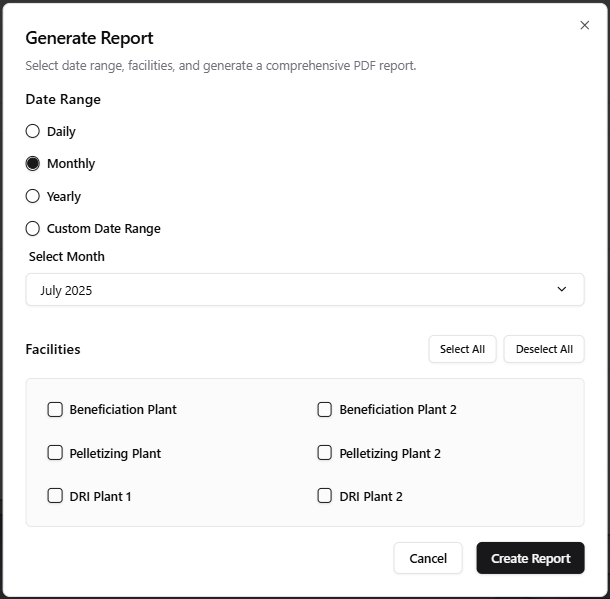

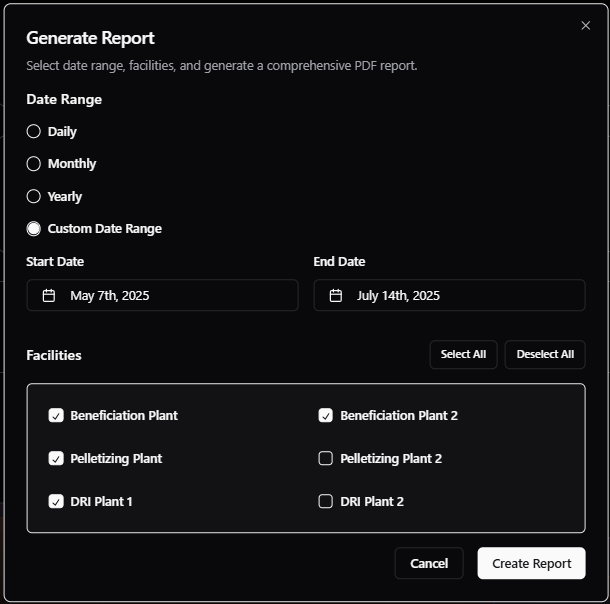

2. Date Range Selection

The system offers flexible date range selection options to accommodate different reporting needs. Users can generate daily reports with 24-hour operational data for specific dates, monthly reports covering complete calendar months, yearly reports for annual performance analysis, or custom date ranges by selecting specific start and end dates. This versatility allows users to analyze operational data across any desired time period, from single-day detailed views to comprehensive annual overviews.

3. Facility Selection

The system supports various facility types including beneficiation, pelletizing, and DRI facilities. Users can select multiple facilities simultaneously using convenient controls like Select All/Deselect All buttons or individual selection, with validation ensuring at least one facility is selected.

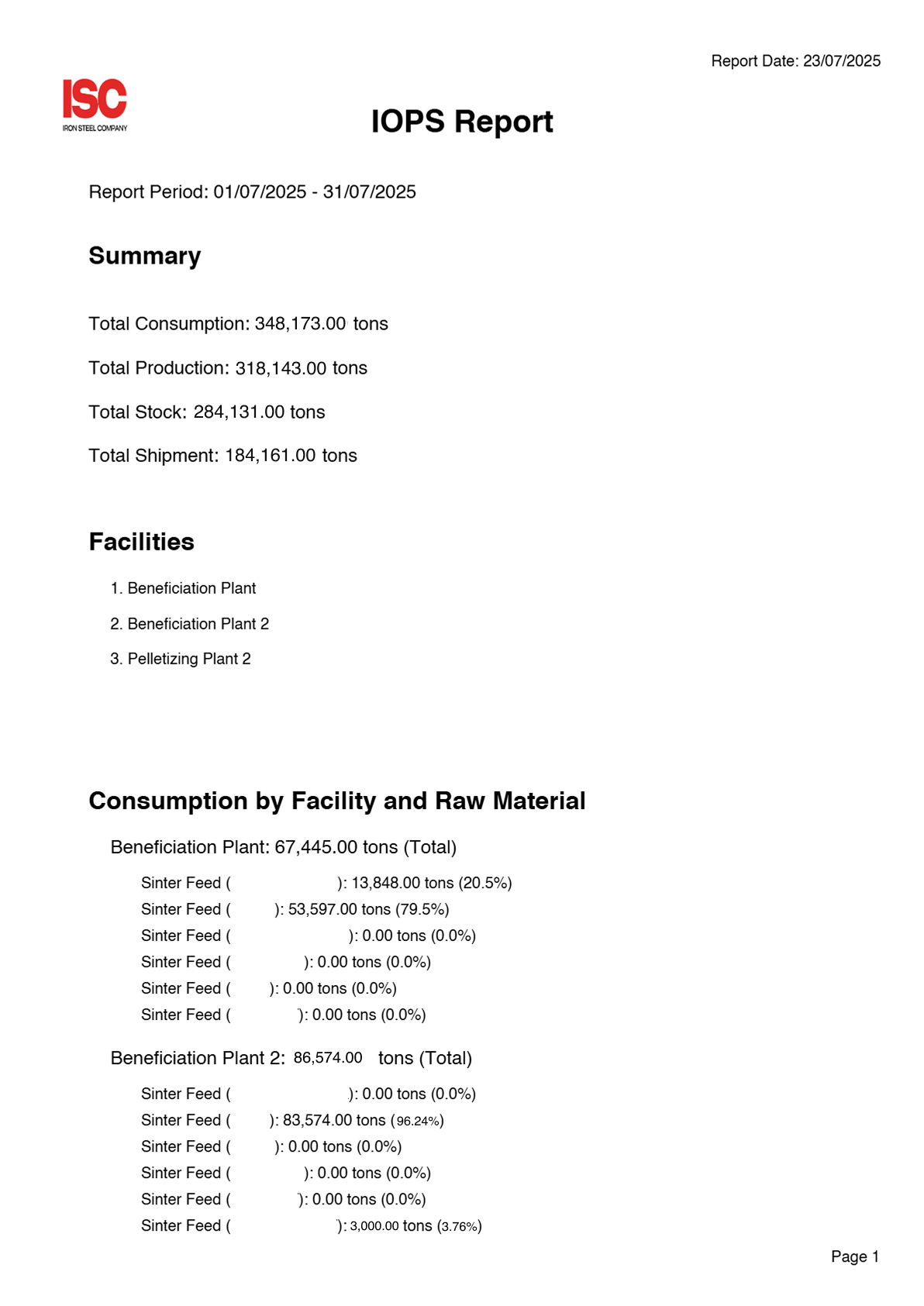

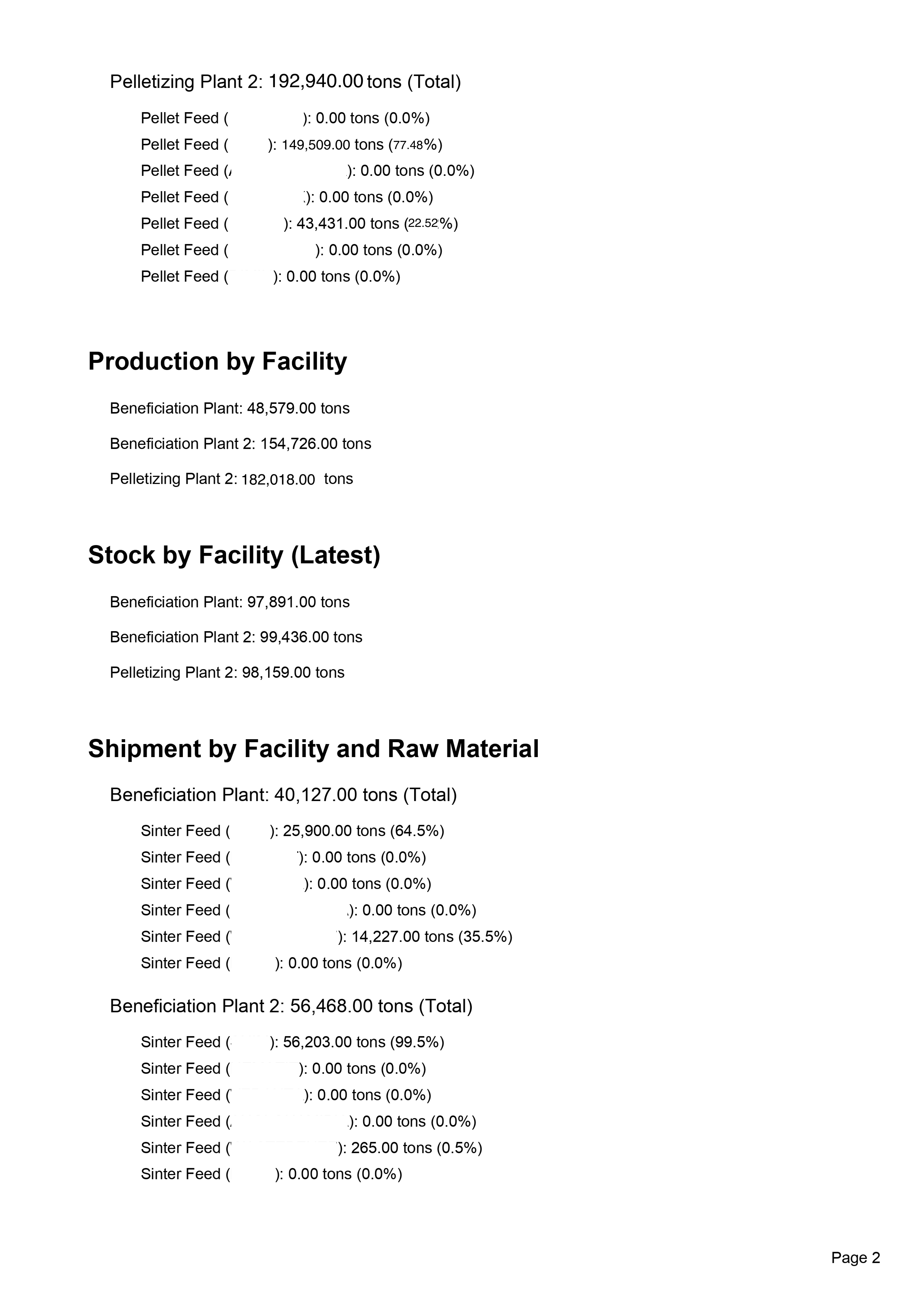

4. Report Content

The generated PDF reports include comprehensive operational data:

Summary Section

- Total Consumption: Combined consumption across selected facilities

- Total Production: Combined production output across facilities

- Total Stock: Current stock levels across all facilities

- Total Shipment: Combined shipment data for selected period

Detailed Sections

- Consumption by Facility: Detailed consumption breakdown by facility and material

- Production by Facility: Production output analysis by facility

- Stock by Facility: Current stock levels by facility

- Shipment by Facility: Shipment data analysis by facility and material

- Detailed Stock Analysis: Latest stock levels by facility and raw material

Report Formatting

- Professional Layout: Clean, organized PDF format

- Company Branding: Company logo and branding

- Page Numbering: Automatic page numbering for multi-page reports

- Turkish Character Support: Proper encoding for Turkish facility names

5. Report Generation Process

The system provides a streamlined report generation workflow:

The report generation process incorporates robust data validation to ensure accuracy, including date and facility validation with clear error handling. The system aggregates data from multiple sources, performs necessary calculations, and generates a professionally formatted PDF report that automatically downloads. Key features include timestamp-based naming conventions, clean layout formatting, real-time data accuracy, and comprehensive coverage of all operational metrics.

6. User Interface Features

The report generation system features a responsive design that works seamlessly across mobile and desktop devices. It includes intuitive date selection controls with support for various date ranges, and a user-friendly facility selection interface with convenient bulk operations and clear organization.

7. Technical Implementation

Backend Integration

- PDF Generation: Server-side PDF generation using jsPDF

- Database Queries: Efficient data retrieval from multiple database tables

- Data Processing: Complex data aggregation and calculation

- File Generation: Professional PDF report creation and delivery

This comprehensive report generation tool provides the foundation for effective operational analysis and decision-making, enabling users to create detailed, professional reports for strategic planning and operational oversight across all iron ore processing facilities.